Condition Monitoring -

Predictive Maintenance

Condition Monitoring Services

- Visual Inspection of your Machines

- Online Condition Monitoring

- Thermography

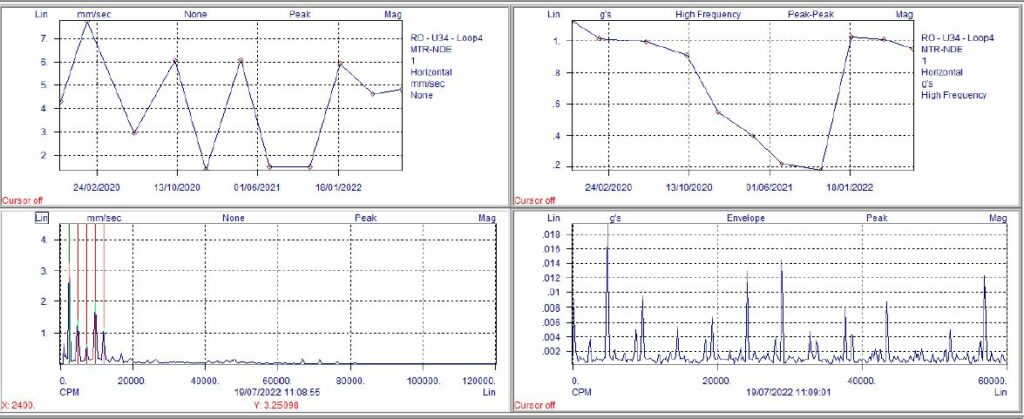

Condition monitoring/predictive maintenance is carried out on the machines health through various means:

Onsite visit – Our engineer/s will call to site to carry out visual inspection of your machines ( gearboxes, pumps, electric motors) with condition monitoring/vibration analysis equipment. A report on the findings is issued to the customer with any remedial work needing carried out to prevent machine failure.

Condition monitoring is a way of regularly monitoring and assessing the condition of equipment or assets to identify any signs of deterioration, faults, or potential failures. It involves the collection and analysis of data related to the performance, health, and operational parameters of the equipment. Condition monitoring is a way to detect early warning signs of machine issues and take appropriate actions, such as maintenance or repair, to prevent equipment failures and increase plant uptime, reducing the risk of unexpected costs to the business.

Online Condition Monitoring

Thermography Condition Monitoring